The owners of new Fanuc CNC milling machines from the Robodrill series already know what am I talking about. At first glance, a transparent and modern-looking touch control panel is visible. And what lies deeper and what possibilities does it have?

Word from producer

The FANUC iHMI user interface has been designed to provide extremely simple operating for the 30i-B, 31i-B5, 31i-B, 32i-B series systems. Intuitive menu icons, clear design and animated effects facilitate the operation of the most complex operations, programs or machine functionalities.

Available machining cycles for turning, milling and measuring.

Possible sizes of LCD panel: 10.4”, 15”, 19”

More details about iHMI you can find HERE.

Screen sections – functions available to the user and its possibilities

The first thing that catches the eye are quite transparent icons and division into four groups of functions:

– PLANNING

– MACHINING

– IMPROVEMENT

– UTILITY

PLANNING has the following options available:

– REMOTE DESKTOP communicate with CAD and CAM on a seperate PC

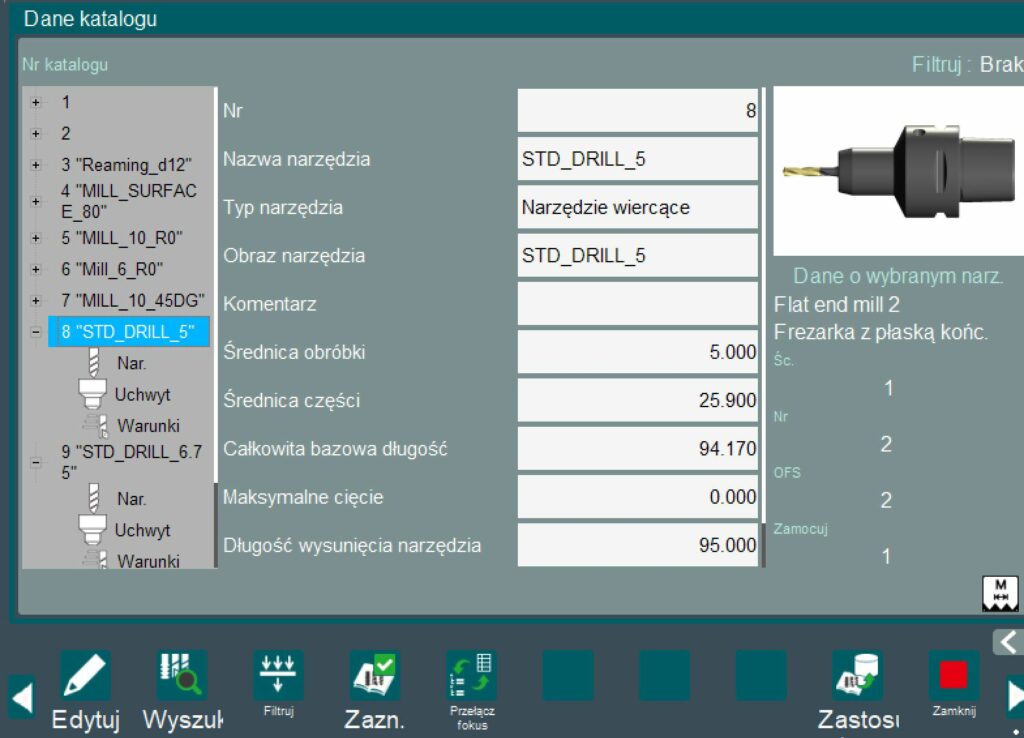

– TOOL MANAGER for managing of tools has been centralised to increase production efficiency

– CALENDAR for planning the tasks

– CYCLE TIME ESTIMATION – estimates quickly the cycle times of the task

MACHINING has the following options available :

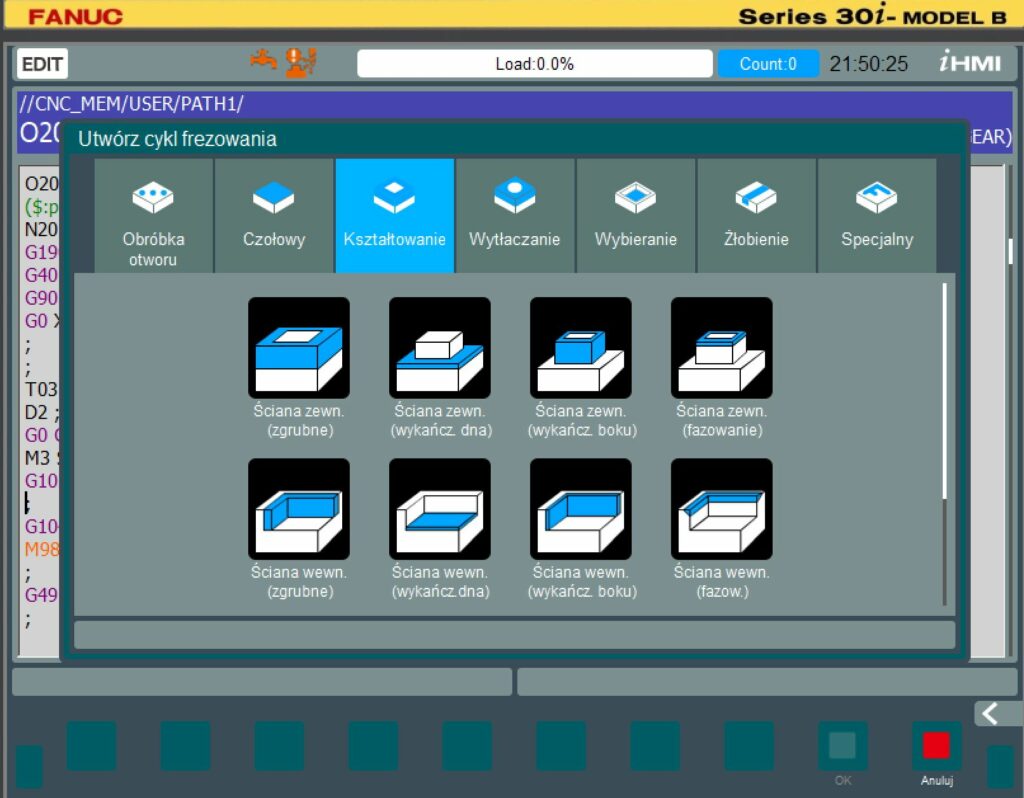

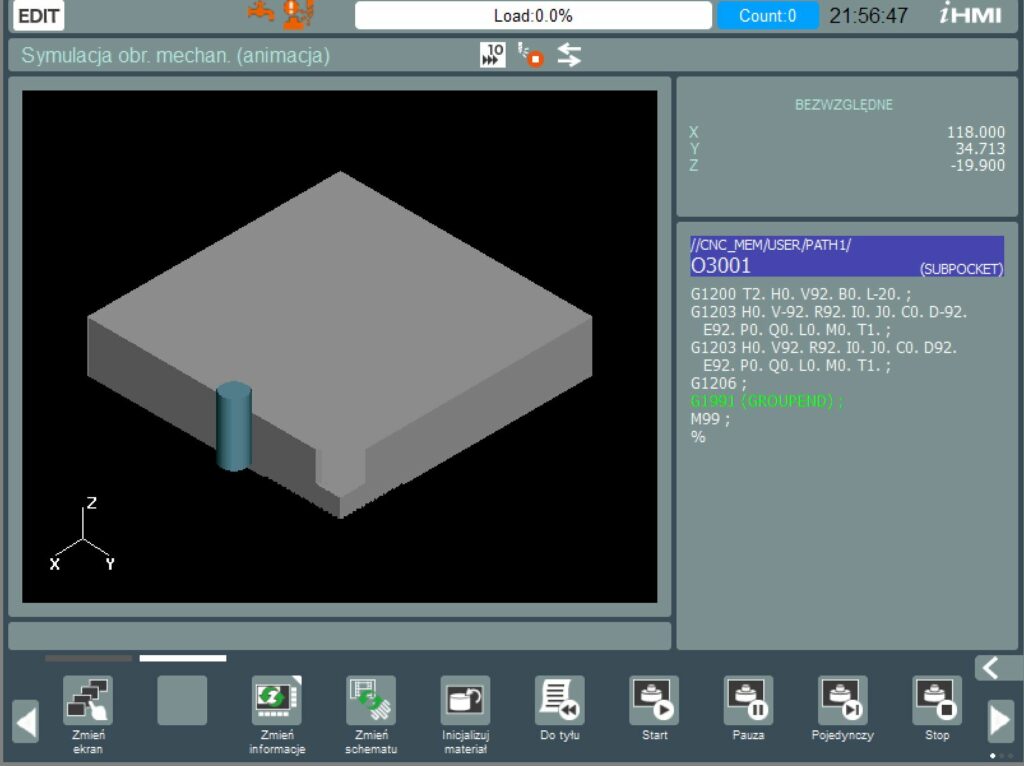

– CNC for setup / edit / operation on a new CNC screen (measuring cycles, fixed cycles, simulation)

– ROBOT – robots can be managed through the CNC interface

– COLLISION AVOIDANCE – The validity of the program and the interference between tool and workpiece can be confirmed by the simulation

IMPROVEMENT has the following options available :

– DATA LOGGER otherwise, production DATA RECORDER and their transmission

– MAINTENANCE INFORMATION – from CNC & Machine is collected to manage such information as life time information of wear parts and the detection of deviations

– OPERATION MONITOR – status information from CNC & machine is collected to display status information, e.g. status information or production overview

UTILITY has the following options available :

– MANUAL – displaying manuals and documentation, help

– MEMO is the window for creating your notes

– BROWSER is of course the browser and e-mail reception as well as network communication with the company’s resources

– MAINTENANCE DISPLAY – display of the familiar interface for maintenance / service

– FILE MANAGER – usage of the well-known Windows Explorer

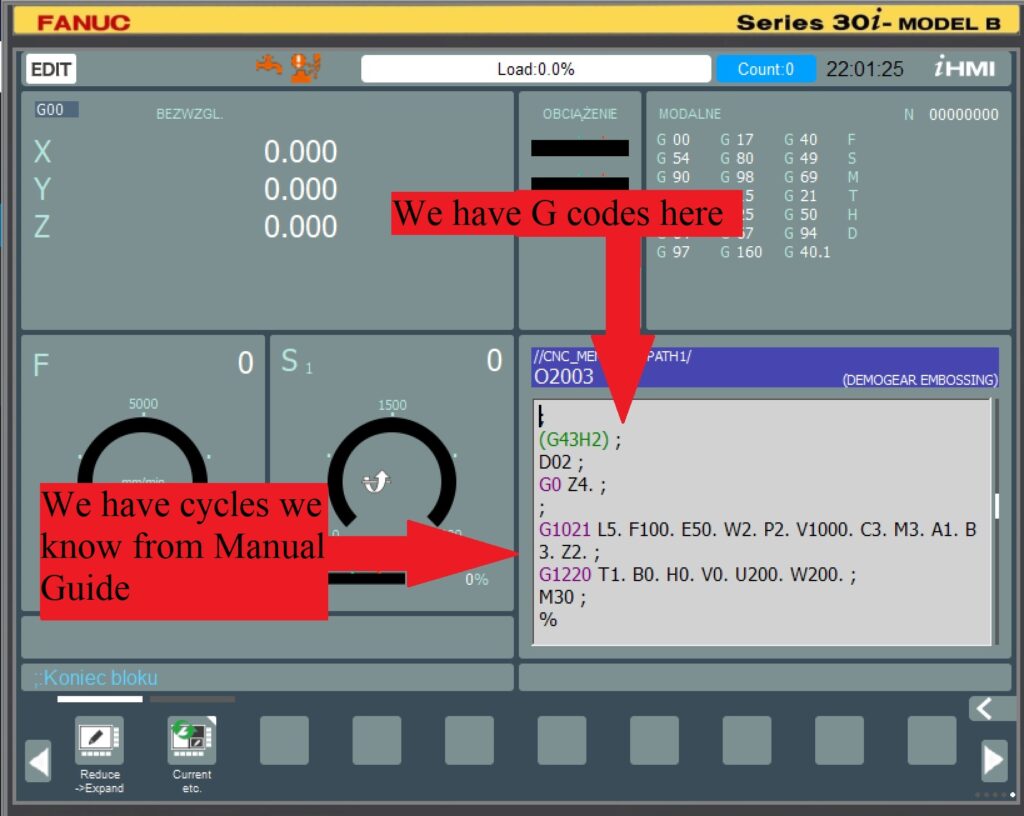

Small presentation – no panic, G codes also remain

Below are some screenshots of various iHMI functions

This is just the beginning…

This article is just an introduction to the whole series of articles, which is to introduce the new system, its capabilities and use. Gradually, on this page I will share all the knowledge I will get in this topic and discover all the possibilities of the system so that it does not have secrets from you.

Since we will be primarily interested in programming, we will usually discuss the options of the first two groups here. However, it is not excluded that we will also mention the others.

Certainly the changes on the desktop are very positive. Pulling out the most important options and dividing them into groups allows you to get to this place in the system quickly and efficiently, which is just needed. Programming looks transparent and intuitive, also simulation functions does. An amazing change in the description of the tools. As for me, a big plus for easy access to documentation from the machine level. Even if I still value paper versions, you can’t always have them on hand at the machine.

All tools for diagnostics and collecting data on the state of the machine are also a great option for any company, regardless of its size, to ensure the efficiency of the machine park and continuity of production. And as the world of manufacturing runs towards “Industry 4.0”, data collection and processing is the basis for implementing its most important elements.