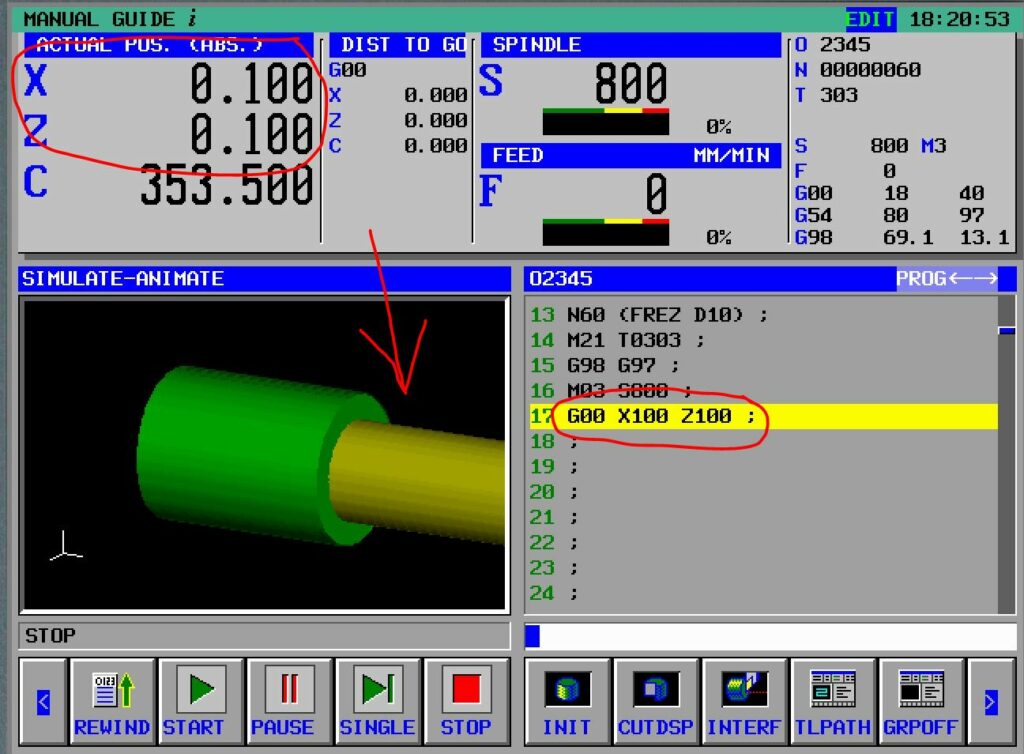

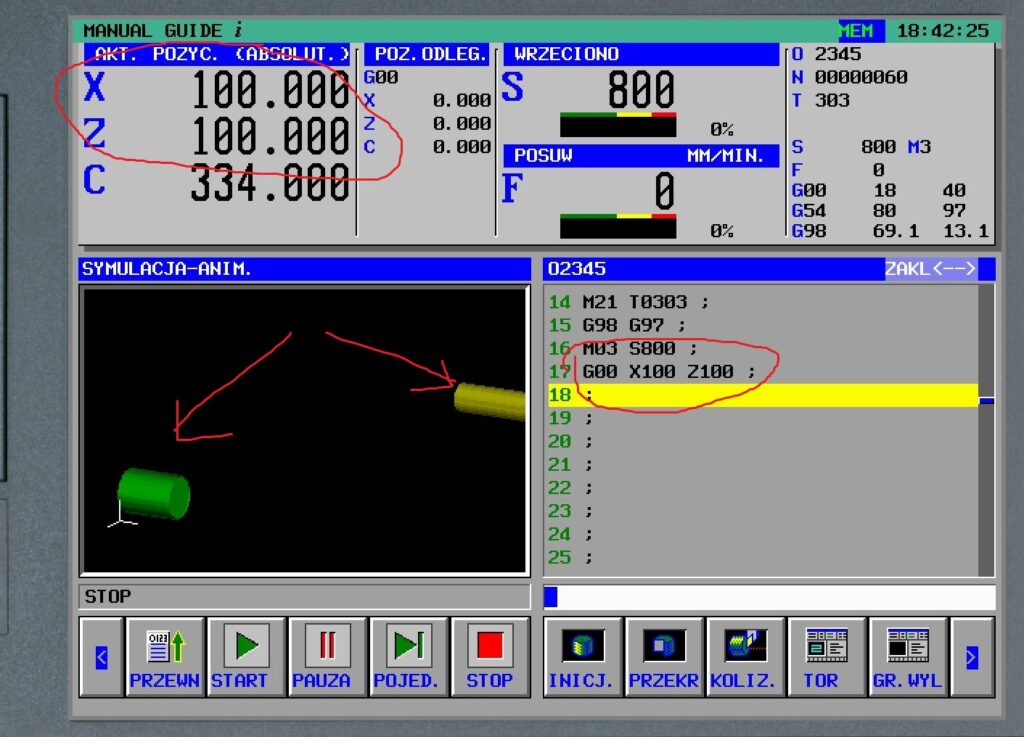

My first collision? It’s rather hard to forget when You make a big crush. Well, for me, the cutting knife on the lathe instead of going away from the chuck entered the material on G0. Theoretically it was ok – “G00X100Z100”

But “the devil is in the details” – the dot got lost somewhere along the way. This was probably my third program written in Windows Notebook many years ago, and some of the machines in that company had to have a dot next to the values and some do not. On two of them, in any case X100 was read in microns, not millimeters. Since then, I have carefully put the dots in, whether it was necessary or not.

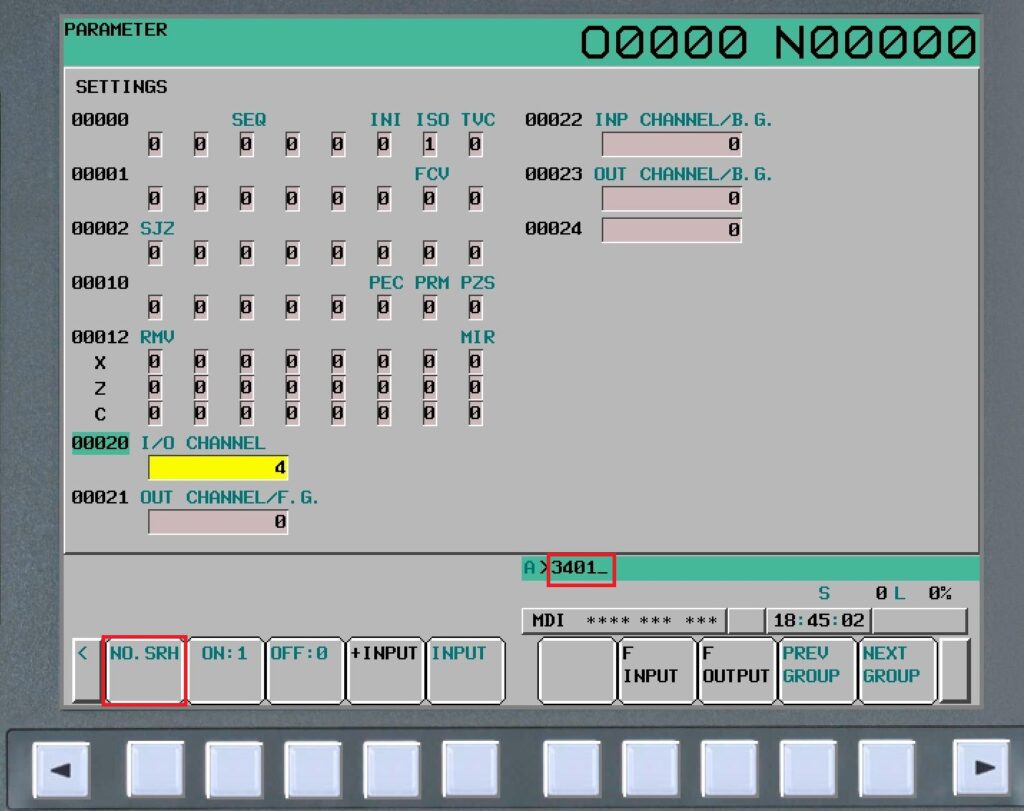

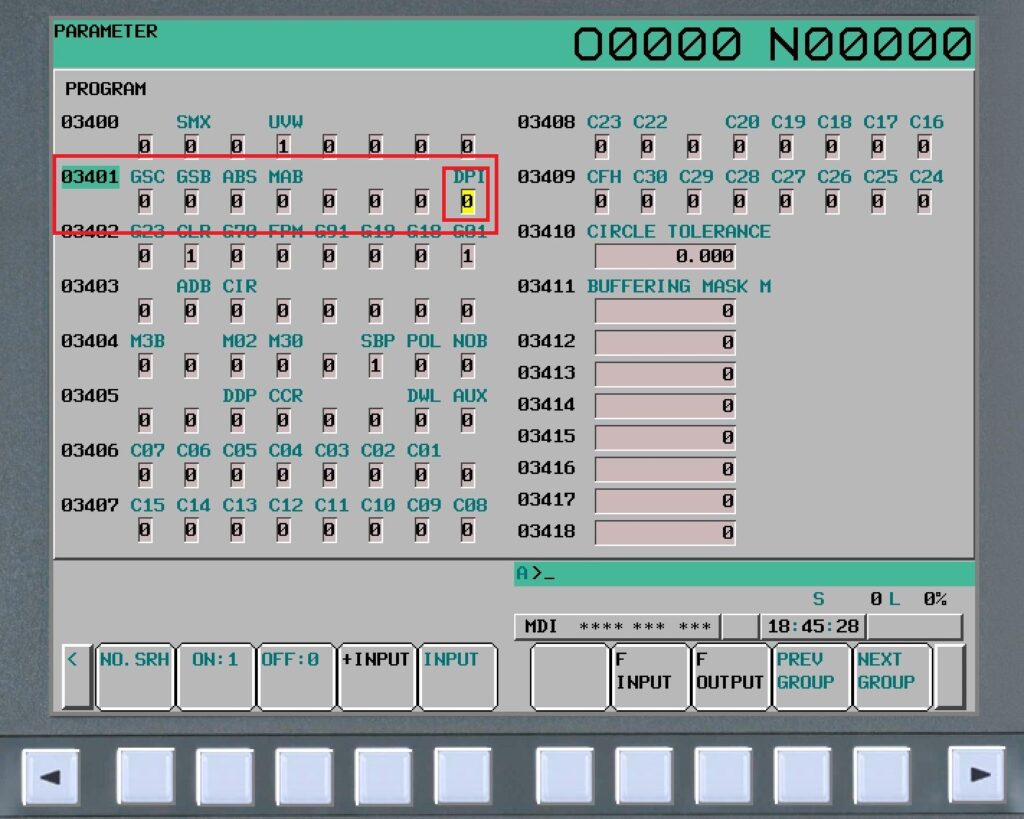

It is a pity that no one knew there what parameter is responsible for it. Then this and some other collisions could be avoided. So for those who do not know, I am proud and happy to present the parameter “3401” – bit zero or DPI (3401.0).

And I think you will become friends.

However, to do anything, we must first enable parameter editing according to the procedure described HERE.

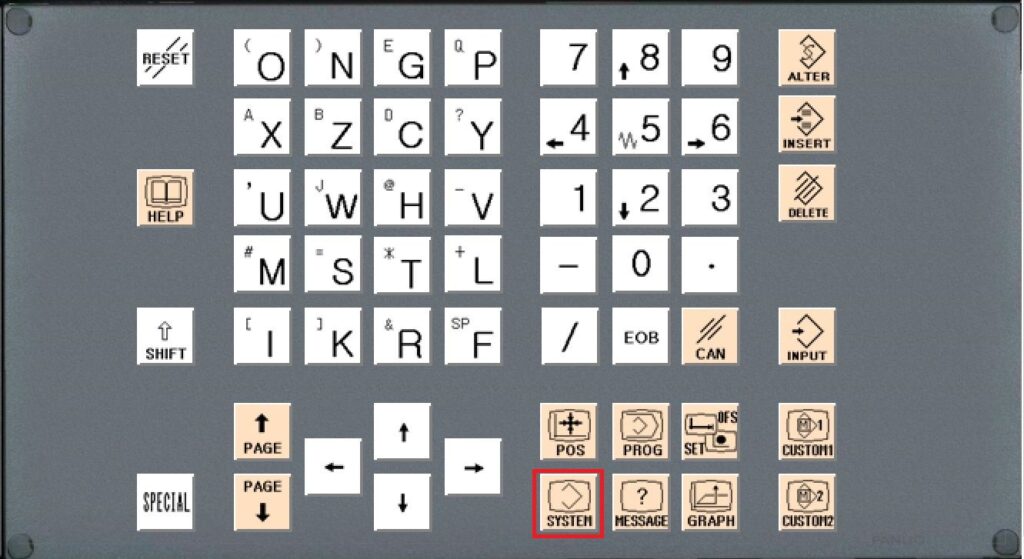

Only then we go to the parameter list via the SYSTEM button.

A window appears with a list of parameters as below. Enter parameter number 3401 and select the command NO. SRH

The last one “zero” bit of this parameter is set to “0”, which means that values without a dot are read in microns.

Enter the value “1” and confirm with INPUT

Now we can be calm that the lost dot will not cause us a mess. We can check if everything is correct, and of course, remember to turn OFF THE POSSIBILITY OF EDITING PARAMETERS.

And how are your collisions? There are some memories. At that time I had “full pants”, but after years I can laugh about it.

Maybe something else bothers you? Who knows? Maybe there is another magical parameter that will remove you the problem?