The story of the Tower of Babel teaches us how the lack of a common language can inhibit development or even completely ruin promising work. Until now, the CNC industry was just like construction site of the Babel tower. However, two years ago there was a breakthrough and something began to change on this topic. I am talking about an umati which is supposed to change this …

What exactly is umati and why do I need it?

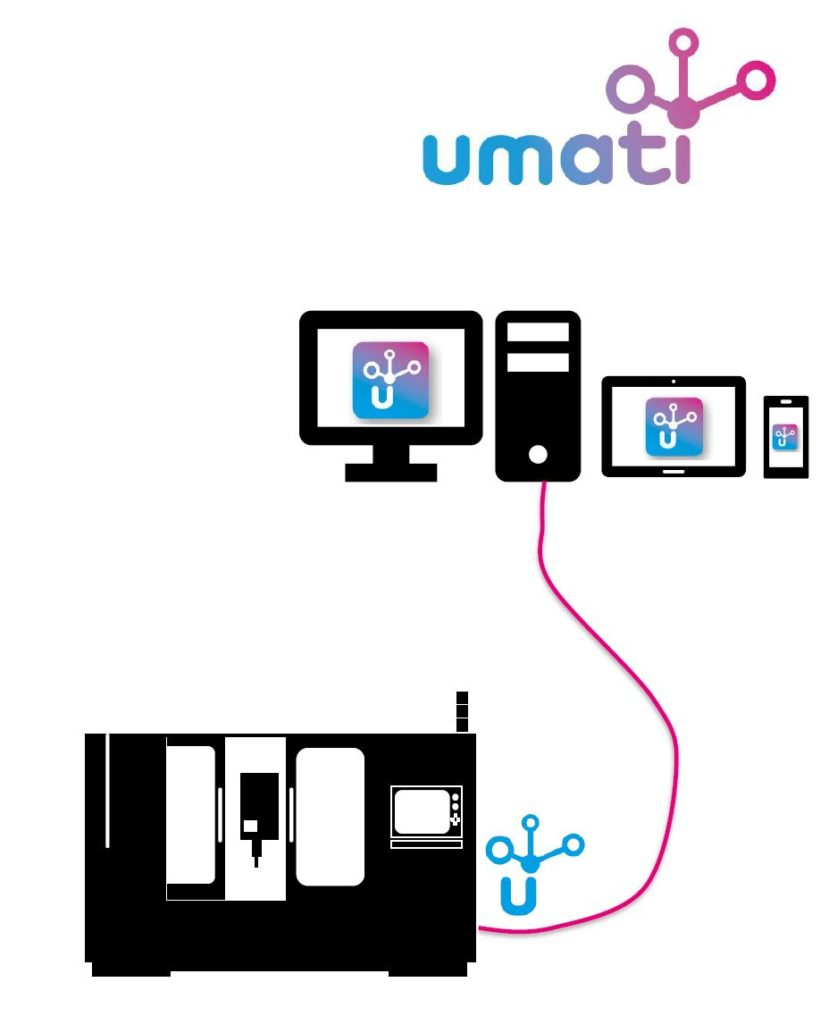

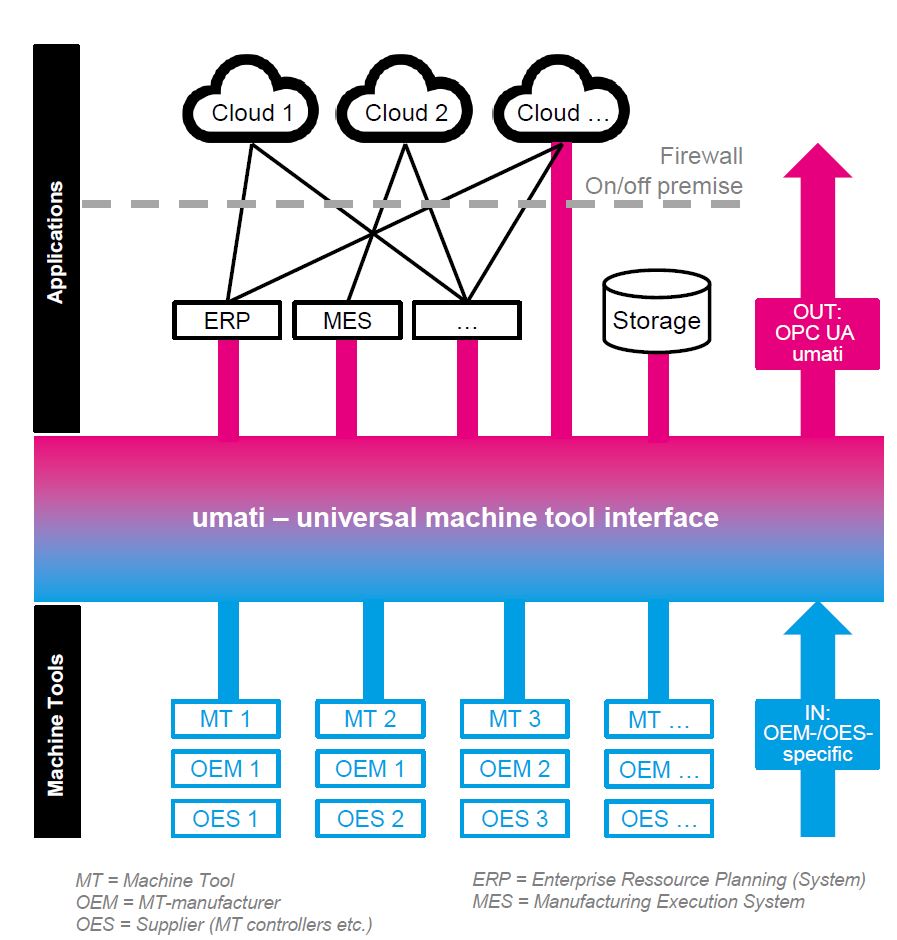

Well now there will be some definition. umati is an shortcut from universal machine tool interface. It enables you to connect machine tools and peripheral devices with customer-specific IT ecosystems – easily, safely and without problems. umati is simply an open standard for machine tool users worldwide. Through easier communication, it allows the full use of the potential of “industry 4.0”, removes barriers and communication restrictions between machines and software.

What does standardization cover?

umati has set itself the goal to create the standard for connecting machine tools to IT systems in the production environment (vertical integration). In the long term, the following parameter groups are covered:

• Uniform machine identification

• Operating state of the machine tool

• Information on production order

• Supply information (energy, material)

• Tools and workpieces

• Storage systems

• Forecasts on user interactions

The focus is on data with an update rate of approx. 1 second. At first, use cases for status monitoring of machine tools are standardized, e.g.:

• Fast overview if production is running

• Job overview, job order

• Errors, alerts and interruptions

• Machine status, state of operation

• Information about upcoming manual intervention

• Unified identification of machine tools from

various suppliers

• Data analytics (program run time, errors,

interruptions, energy and other consumables)

• OEE analysis

• Tool management

Why OPC UA?

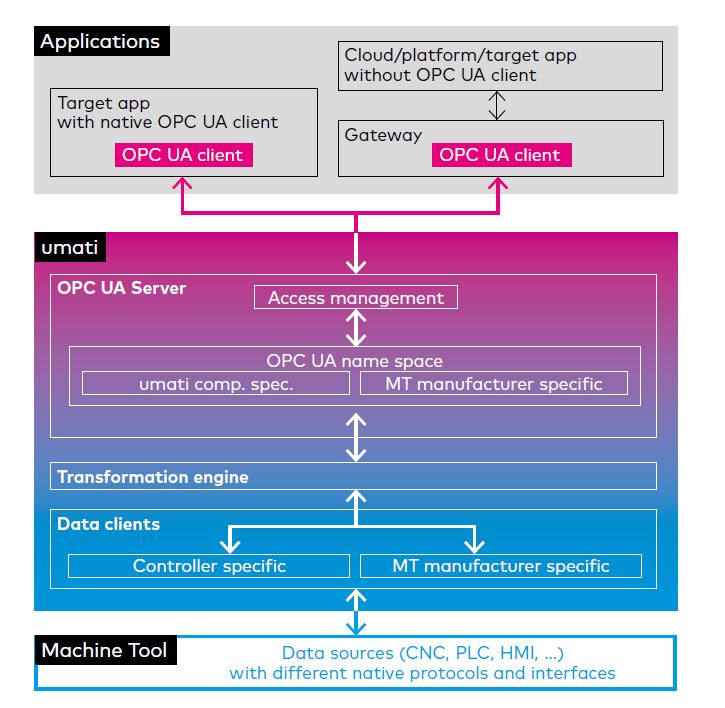

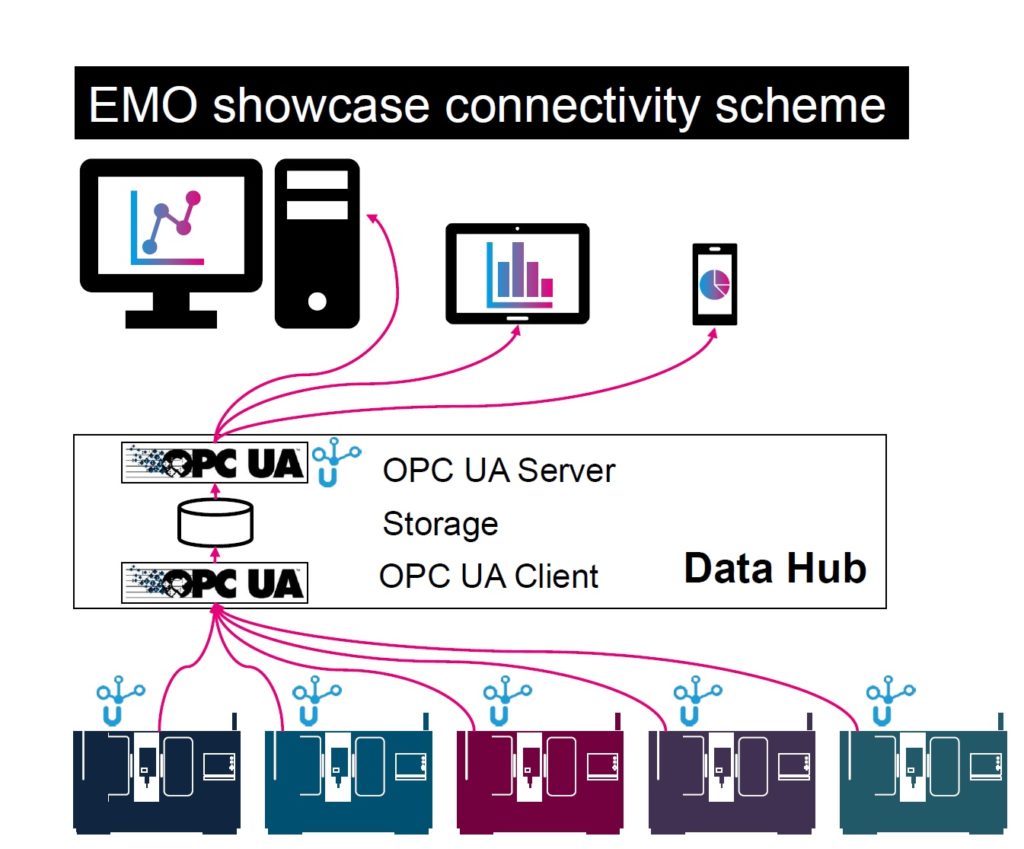

Umati creates standardized semantics embedded in an information model based on the OPC UA open communication standard. OPC Unified Architecture (OPC UA) is an industrial M2M (machine-to-machine) communication standard created by the OPC Foundation. It is a technology based on generally used communication standards such as TCP / IP, HTTP and SOAP. OPC UA can also work on platforms other than Windows, and OPC UA communication can also be built into PLCs and other devices. Thus, the choice of OPC UA is from the very beginning the choice of a standardized communication structure of various systems in an automation environment.

Where did it actually start? A bit of history, but also of the future

umati was initiated by VDW (German association of machine manufacturers) and announced at EMO 2017. Initially, the basic group consisted of 10 machine manufacturers + 1 research institution + VDW staff. Their vision was:

➢ exploiting data creates an added value for customers, thus leading to new, trendsetting business models for the sector

➢ open interfaces to exchange data between machines and IT systems are the basic requirement for Industrie 4.0 / IIoT

➢ pecification of open interfaces must be undertaken by the machine tool industry itself, to cover the specific needs of its customers

➢ collaboration yields no competition, does not oppose individual advantage in the market

➢ get interested participants from all over the world involved from the start.

In September 2018, the design group made their first live presentation at the AMB 2018 international metalworking trade fair. In numbers it was: 18 machines, 9 manufacturers, supplied by 5 control manufacturers that exchanged data based on the umati standard.

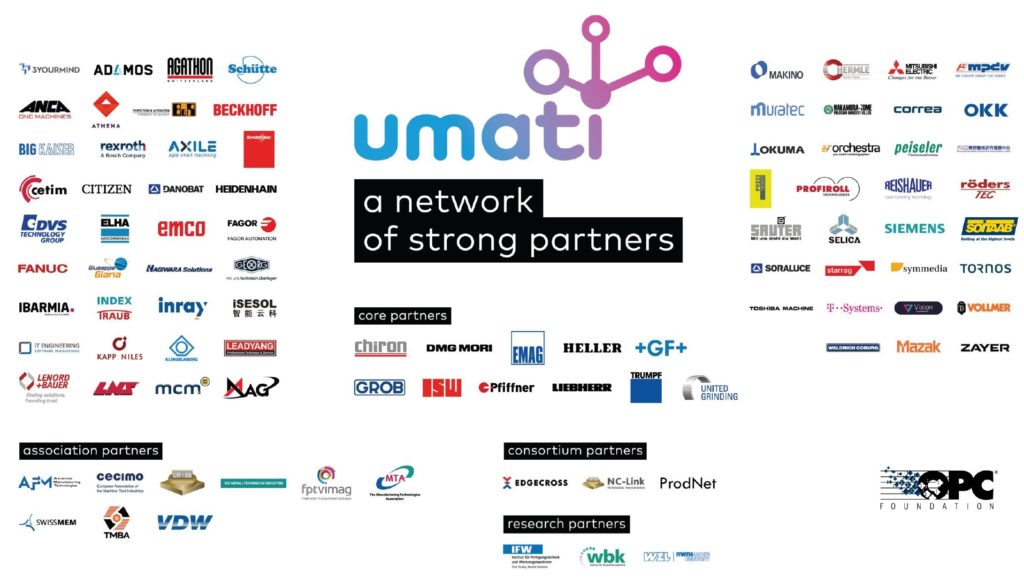

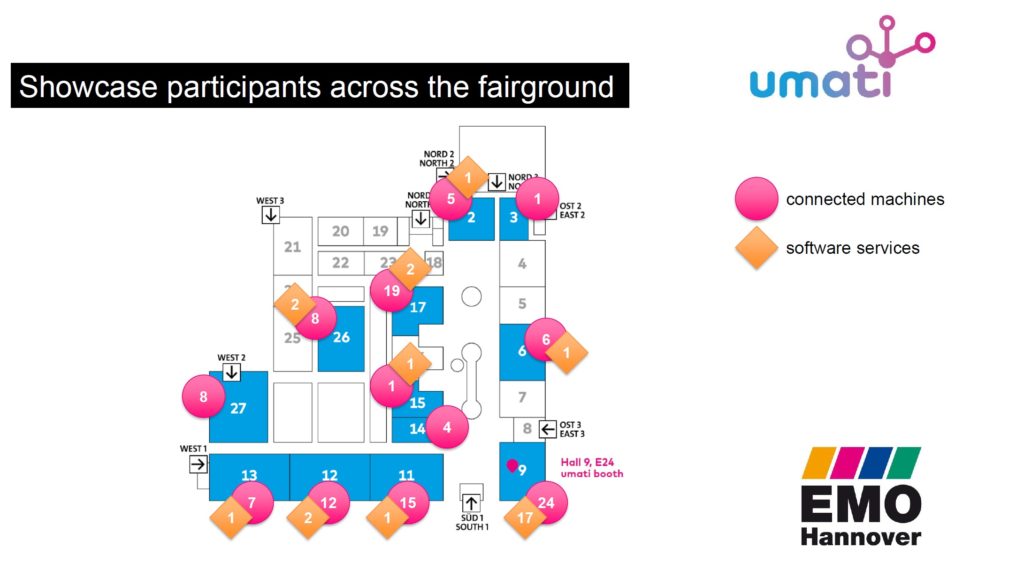

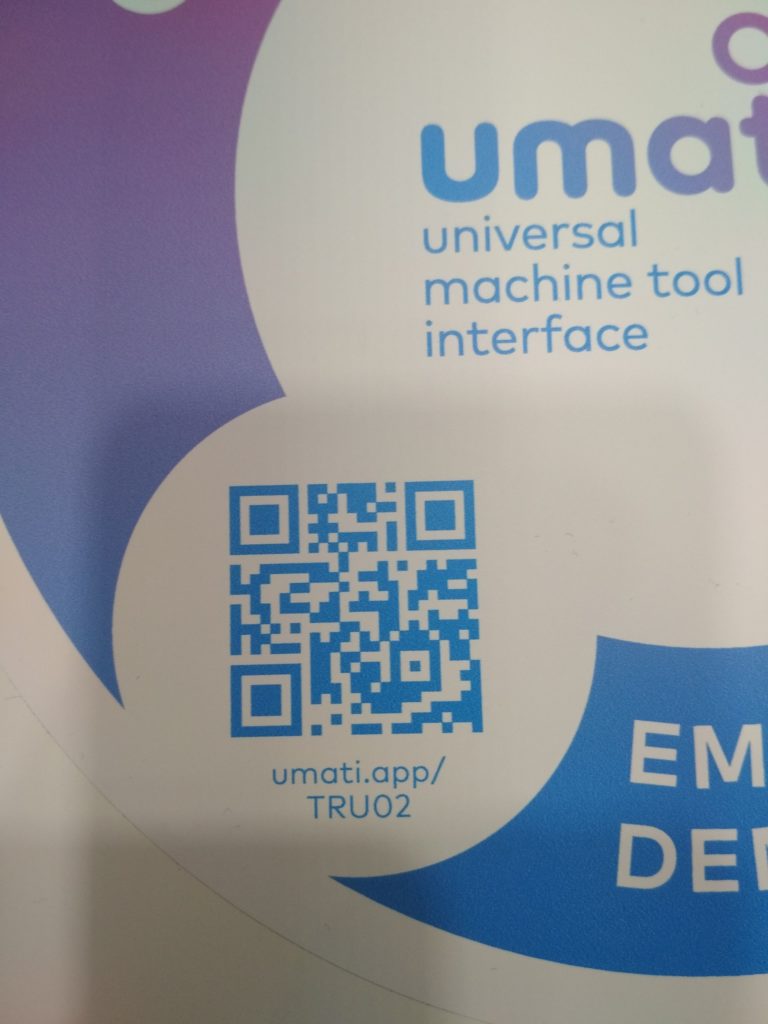

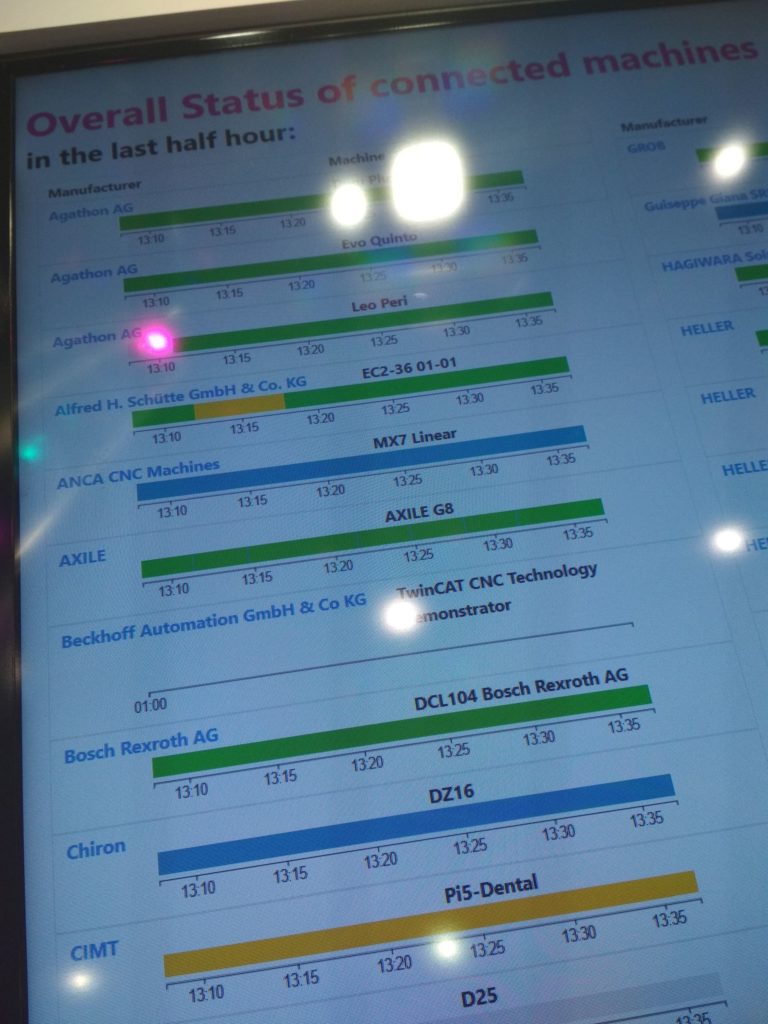

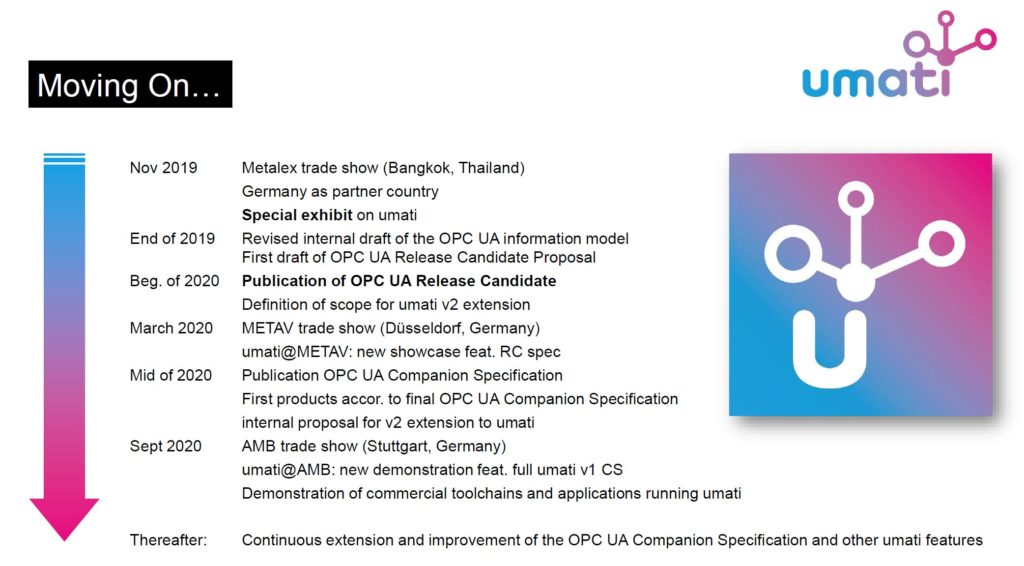

During the EMO 2019 in Hannover, another live presentation was made – the numbers are impressive. 70 companies, 110 machines, 28 software solutions from 10 countries took part in the project. By using the QR code or link you could have a preview of all these machines at https://umati.app. Each connected machine had a marking.

On the subject of umati and related topics, you could expand your knowledge at the umati stand in Hall 9 and in numerous lectures, equally in the same hall. Friday was a thematic day entirely devoted to umati issues.

I had the opportunity to participate in all this, talk to experts and observe the status of machines from different manufacturers in different halls. I will be constantly watching the further work related to the project, and by spreading information about umati I want to make a small contribution to this sensational project.

If someone else also wants to be up to date, I recommend the website www.umati.info, it is also possible to become a partner, co-creator of subsequent trade fair events or express interest in news regarding the development of umati by registering on the mail info@umati.info and observing the #umati hashtag

The article is not sponsored in any way. It is the result of my visit to the umati stand during EMO 2019 and an expression of my support for the whole idea of standardization. Thank you also for all materials and information that has been given to me.